Impact Recording Device (IRD)

TM

We understand the needs of the agricultural community because we are a part of it! That's why the IRD is still the Global Standard.

The IMPACT RECORDING DEVICE (IRD) is an advanced technology tool for monitoring potentially damaging impacts to your fruits, vegetables and food products. From the field to the processed package and all points in between, the IRD will identify sources of damage allowing you to make adjustments to handling systems and protect quality.

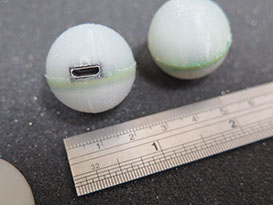

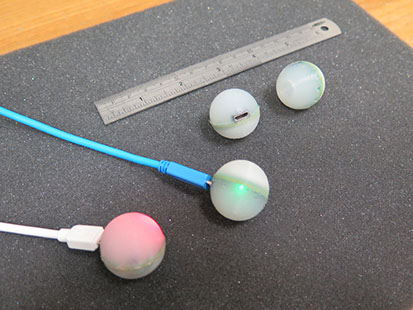

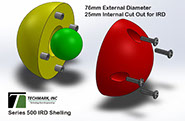

Techmar's IRD is not a multi-tool. It measures the impact force and time duration of the impact event. The time duration paired with the G-Force of impact creates a more thorough understanding of bruise potential in your fruit and vegetable crops. Techmark's unique shelling system creates value by allowing commodities of different sizes to be tested using the same sensor kit. The core 25mm (1 inch) sensor can be deployed on its own or used inside a shell. The shells are designed with materials that imitate qualities of fruit and vegetables including the need to "give" during impact and impact energy dispersal.

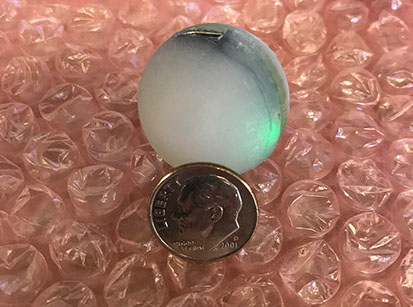

We use spherical shelling to create a consistent data set for the repetitive testing that is standard when evaluating handling systems. A sphere is the most scientifically consistent shape as all points of impact are equidistant to the sensor where the impact force is measured. The user can also deploy the sensor inside of the actual fruit or vegetable in some cases.

The IRD is used around the globe by some of the largest organizations in the industry. It can be used on small farms or large processors to identify where damage is occurring and loss is happening.

Force and Duration of Impact are the true measures of Damage Potential

Many devices on the market measure only the G force and ignore the important component of time duration. Not all impacts are created equal. Surface characteristics, G force and duration all contribute to understanding what impacts are of importance and which are less so to your product quality. The time duration of an impact is a reflection of the surface characteristics the impact is occurring with.

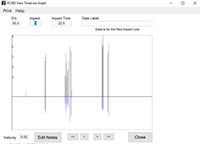

Using internationally patented technology the IRD identifies the location and severity of impacts delivered to produce during handling procedures. The IRD is transferred through machinery and other handling systems with the normal course of fruit and produce, this allows the IRD to experience the same "bumps and bruises" that your commodity is experiencing. Impact data is recorded and stored on board the IRD, later this data is uploaded to your tablet or PC for analysis. PCIRD, our IRD software package, will generate reports from the data collected and allow for straight forward interpretation of where the most significant impacts occur.

The Science

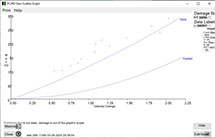

Severity of impacts is calculated in both maximum acceleration (G) and velocity (m/s) for each impact. This is the key to understanding where the damaging impacts occur; not all impacts create damage, to separate the non-damaging impacts from the damaging impacts you must know BOTH the acceleration and the velocity.

To better understand this process, imagine an apple being dropped from 12 inches onto a rubber surface. Now imagine the same apple being dropped onto concrete. It is possible in this scenario that the impact G force is the same for both drops BUT the damage caused is significantly different because of surface characteristics. The rubber surface will be able to absorb the G force over a greater amount of time thereby changing the velocity and causing less damage to the apple. The concrete will have a short time period of velocity change and the energy of the G forces will cause damage to the apple in the form of bruise as the energy is absorbed by the fruit. What does this mean for you? It means that the IRD can identify where bruising potential exists and allow you to make a change. Sometimes the change is as simple as reducing a drop or adding a padding material to a corner. Other damage points may be less identifiable and need more significant alterations to avoid product damage.

The spherical shape of the IRD creates a consistent evaluation of the handling system. All points on a sphere are equidistant from the center. This shape provides a consistent interaction with the systems it travels through. No fruit or vegetable is of exactly the same dimensions, neither are the handling systems they move through making it important to use a measuring device of a consistent shape and weight to provide reliable data that can be compared to other data generated in the same manner.

Techmark's IRD is a global standard for evaluating fruit and vegetable handling systems.

<

>

Series 500 IRD

1 Inch IRD for small fruit

Our 2mm (1 inch) impact sensor is great or small fruit. The IRD is being used worldwide in the small fruit industry to identify ways to improve handling systems. The cherry industry, in particular, has adopted wide spread use during handling processes including harvest and packing. We work with users to identify best practices and implement productive testing programs. Reducing mechanical damage by even 1% can have significant positive impact on fruit quality and the bottom line!

Consulting and Special Projects

Techmark offers consulting on a project basis. We can quote a specific project or training session after talking with you about your goals and the scope of the work. We have worked on handling system worldwide and can help you identify best practices as well as train staff in using the IRD to conduct evaluations of handling systems and processes. Our consulting takes many shapes. We can bring our equipment to site and perform the testing or we can visit your site to train your staff in best practices.

To discuss an on-site consulting project please contact us at techmark@techmark-inc.com

5 - 14

<

>

How much is bruise and physical damage costing your organization each season?

Impact data can show where the most damaging impacts are occurring and allow you to make changes which reduct them

Data Visualization

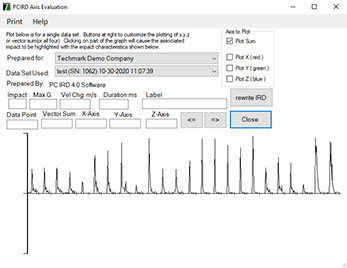

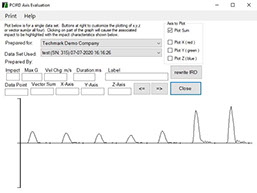

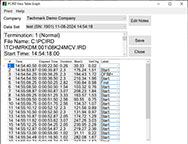

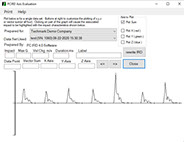

Data is displayed in several formats by our PCIRD software. Raw data can be exported into spreadsheets for further analysis. PCIRD offers data as an Axis Evaluation, Scatter Plot Graph, Table Graph and a Time Line Graph. Each data graph has its uses an many users have preferences for interacting and organizing the data.

The Series 500 IRD uses a shelling system to create flexibility for the user with multiple crops to evaluate. We use spheres because they are the most scientifically appropriate shape. In a sphere, all points of impact are equidistant from the center where the impact is measured. This is particularly important for repetitive testing where data sets can illustrate trends and require consistent testing methodologies with repeatability.

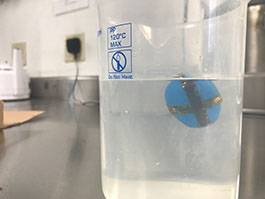

We have a number of stanard sizes for our shelling. 89mm (3.in),76mm (3.0in), and 63mm (2.5in) are all popular sizes. We also have a 76mm shell that floats - useful in systems that use water to move fruit i.e, apples and others.

We can also make custom shell sizes and limited shapes using 3D printing. An example is this Chinese Plum shell we made or a producer and handler in Asia. As you can see the shell is only slightly larger than the sensor and we maintained neutral buoyancy.

Techmark Inc. Technology from the ground up 1-517-322-0250 www.techmark-inc.com techmark@techmark-inc.com

Techmark, Inc.

15400 S. US 27

Lansing MI 48906

All materials copyrighted.

2025